Level-Trac : Water Level Indicators

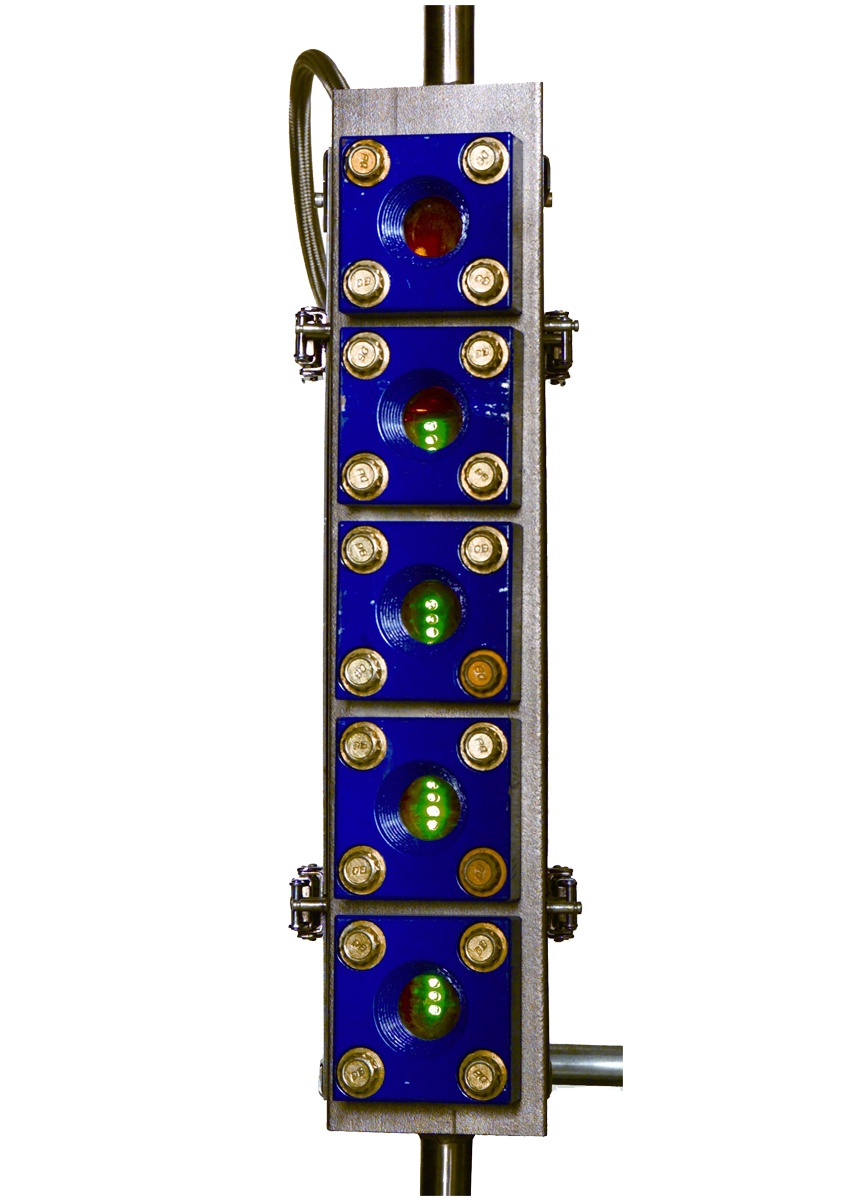

Level-Trac LT-500

The Level-Trac Model 500 probe manifold features sturdy construction in full compliance with ASME Section 1 requirements. Each column is custom built to the customer’s individual specifications. The chamber is a custom extrusion designed to provide full probe thread engagement. The Model 500 probe column may be used as an independent remote level indicator per ASME PG-60 Section 1, or as a traditional water column for the mounting of direct reading sight glasses. All piping connections are to user specifications.

Level-Trac LT 501

The Level-Trac Model 501 probe column features sturdy construction in full compliance with ASME requirements. Each column is custom built to the customer’s individual specifications. The Model 501 Water Column may be used as an independent remote level indicator per ASME PG-60, or as a traditional water column for the mounting of direct reading sight glasses. All piping connections are to user specifications.

Level-Trac LT 502

The Level-Trac Model 502 probe column features sturdy construction in full compliance with ASME requirements. Each column is custom built to the customer’s individual specifications. The Level-Lock probe insert is made of 316 Stainless Steel. The metal-to-metal ferrule seat eliminates the possibility of gasket failure, a common field problem with competitive models.

Level-Trac LT 420

The LT-420 is a unique device used for water level indication on Section I boilers and other boiler feedwater applications. The unit combines several standard features in order to satisfy modern boiler code requirements, and at same time address challenging aspects of water/steam level applications. ASME BPVC.I-2019 PG-60.1.1 requires a Remote Level Indicator (RLI), to continuously measure, transmit and display the water level in the control room.

Level-Trac LT-40 / LT-41

Questtec Level-Trac LT-40 / LT-41 probe fixtures are a simple device to provide a means of point level water indication to be used for alarms or trips. The fixture is designed to be piped in to a vertical configuration to track the contents of a steam drum or other pressure vessel.

Level-Trac LT 430

The Quest-Tec LT-430 provides an exclusive means of achieving accuracy with Guided Wave Radar, or any other loop powered instrument, when used in a water column to determine level in a high pressure steam system. The LT-430 utilizes the data collected from at least 4 thermocouples installed on the water column and determines an actual average water temperature. The primary loop is dynamically corrected and a secondary loop is communicated to any device included in the loop.

Level-Trac LT 310

The Level-Trac LT-310 is a remote level indication system, as described in ASME Section I, PG-60. The system may also be used as an alarm or trip device. The Level-Trac Model-LT-310 water detection control unit can be used to drive up to six conductivity/resistance probes installed in a single column or separately. The unit features complete redundant and discrete channels, with two independent power supplies. Channel interaction can be entirely discrete, coincidental or based on 2 of 3 voting logic.

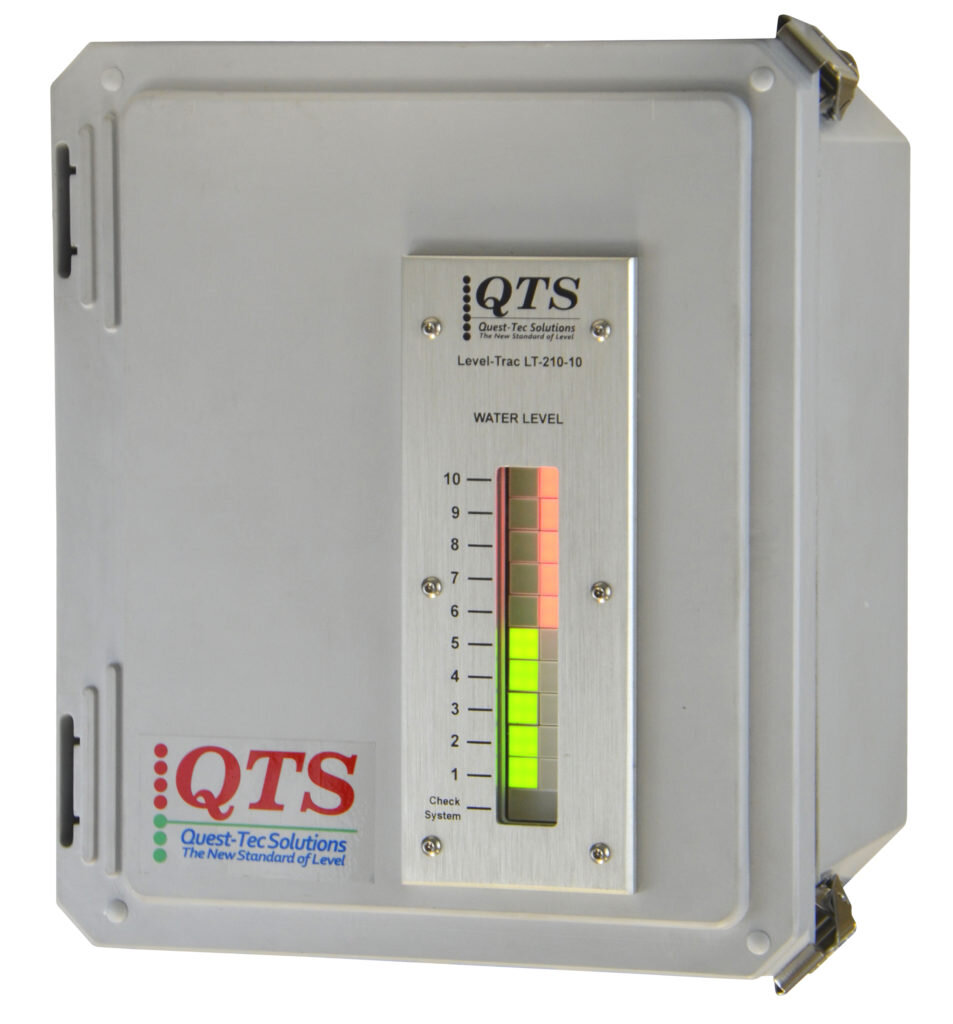

Level-Trac LT 210

The Level-Trac Model LT-210 Electronic Control Unit is a component of a remote level indication system, as described in ASME Section I, PG-60. The control unit may also be used as an alarm or trip device. Discrimination between water and steam is based on the significant difference in resistivity between the two states over the saturation range. The control unit interprets and displays the signal from up to 12 probes mounted in a probe manifold. Via voltage applied to the probe tip, conduction in the presence of water will occur between the tip and the inside wall of the column.

Level-Trac LT 220

The Level-Trac Model LT-220 Electronic Control Unit is a component of a remote level indication system, as described in ASME Section I, PG-60. The control unit may also be used as an alarm or trip device. Discrimination between water and steam is based on the significant difference in resistivity between the two states over the saturation range. The control unit interprets and displays the signal from up to 14 probes mounted in a probe manifold.

Level-Trac LT 120

Level-Trac LT-120 Control Units are designed to be used with any conductivity probes used for the discrimination of water and vapor (steam). The Control Unit delivers a low voltage common signal to a water column, which completes a circuit when a probe installed on the water column makes contact with water. The Control Unit provides the user with a sect of contacts for each probe, and the facility for an optional indicator. Control Units are generally installed nearby the water column, but may be installed up to 1000 feet away.

Level-Trac LT 140

Level-Trac LT-140 Control Units are designed to be used with any conductivity probes used for the discrimination of water and vapor (steam). The Control Unit delivers a low voltage common signal to a water column, which completes a circuit when a probe installed on the water column makes contact with water. The Control Unit provides the user with a sect of contacts for each probe, and the facility for an optional indicator. Control Units are generally installed nearby the water column, but may be installed up to 1000 feet away.

Magne-Trac : Liquid Level Indicators

Magne-Trac Standard

The Magne-Trac product line provides one of the safest and most economical ways to meet your level measurement requirements. In applications for extreme pressure, temperature, vibration, and highly corrosive or hazardous material, Magne-Trac gauge will perform where other fail. Features include lower installation costs, easy to read liquid level indication, and low maintenance.

Magne-Trac Plus

The Magne-Trac Plus combines a Magne-Trac magnetic level indicator with a Bridle-Trac bypass chamber, in which a customer specified guided wave or non-contact radar may be installed. Although either instrument may be connected to the vessel, Questtec recommends that the bridle functions as the primary chamber. By using the magnetic gauge as the secondary chamber, the customer will have the option to rotate the indicator up to 180 degrees easily in the field. The two chambers may welded or flanged together; QTS recommends installing valves in between the magnetic gauge and bridle chamber so one may be isolated if necessary.

Bridle-Trac

The Questtec Solutions Bridle-Trac utilizes a pipe chamber mounted directly to a vessel with two or more process connections. These connections act as an inlet and outlet that allow the liquid level in the pipe chamber to match the level in the process vessel. A bridle-trac may be referred to in the industry as a bridle chamber, a stilling well, a bypass chamber, a cage or a standpipe. It may be used with a customer specified radar for level measurement.

Eco Trac

In applications that are low pressure and operating near or at ambient pressure a QTS Eco-Trac is an alternative solution to fragile tubular glass. For limited liability units, the Eco-Trac is designed for easy to read level indication in a reduced cost efficient package. Best suited for but not limited to applications such as skid systems, boiler feed water tanks, refrigeration units, wastewater treatment facilities, etc.

MTLT - 5000

The MTLT-5000 is based upon the magnetostrictive principle. The sensing tube contains a wire which is pulsed at fixed time intervals. The interaction of the current pulse with the magnetic field created by the magnetic float causes a torsion stress wave to be induced in the wire. This torsion propagates along the wire at a known velocity, from the position of the magnetic float and toward both ends of the wire. A patented piezo-magnetic sensing element placed in the transmitter assembly converts the received mechanical torsion into an electrical return pulse.

Magne-Trac Plus

The QTS Maverick In-Tank transmitter is configured with a flexible hose constructed of 316L stainless steel that can be ordered in lengths from 120 inches to 866 inches with a 4-20mA. Once installed and calibrated there is no requirement for scheduled maintenance or recalibration.

MTLS - 1A

QTS offers a complete series of point level switches. MTLS-1A switches mount onto the magnetic level gauge chamber. As the magnetic level gauge float travels, it activates the switch through the chamber. Easily adjustable on the chamber, MTLS-1A switches provide low cost, dependable alarm solutions without having to make alternative modifications to the vessel.

MTLS - 5A

QTS offers a complete series of point level switches. MTLS-5A switches mount onto the magnetic level gauge chamber. As the magnetic level gauge float travels, it activates the switch through the chamber. Easily adjustable on the chamber, MTLS-5A switches provide low cost, dependable alarm solutions without having to make alternative modifications to the vessel.

MTLS - 10A

The MTLS-10A is a weatherproof and explosion-proof housed magnetically-actuated electric switch designed for chamber exterior mounting on a Mange-Trac or Magne-Trac Plus magnetic level indicator having a magnetic float that rides a liquid level. The MTLS-10A provides electrical current switching via two isolation single pull double throw (SPDT) normally open or normally closed contacts and is configured for double pole double throw (DPDT) operation such that two separate devices can be controlled with a single switch within the switch rating.

MTLS - PNEU

Questtec Solutions MTLS-PNEU Pneumatic Switch deliver a consistent point switching in magnetic level applications to trigger alarms and to open and close valves with pneumatic actuators. This non-bleed, block and bleed pneumatic switch functions according to the rise or fall of the magnetic float according to the level condition.

Steam-Trac : Liquid Level Indicators

Steam-Trac STB-3000

The Steam-Trac STB-3000 Bi-Color Ported Gauge must be used with a red/green filter illuminator. The gauge chamber is constructed with opposing ports at an angle so that red light will pass unimpeded through the gauge in the steam phase. When water is present, refraction will allow green light, only, to pass through. The result is a clear visual indication of water level.

Steam-Trac ST-1600

Steam-Trac ST-1600 steam gauges are ruggedly built to set the industry standard for reliability in the difficult mid-pressure range from 1000 to 1600 PSI Working Steam Pressure. All materials and construction standards are within strict compliance of ASME Section 1 code requirements.

Steam-Trac ST-1000

Steam-Trac ST-1000 steam gauges are ruggedly built to set the industry standard for reliability. All materials and construction standards are within strict compliance of ASME Section 1 code requirements.

Steam-Trac ST-450

Steam-Trac ST-600 steam gauges are ruggedly built to set the industry standard for reliability. All materials and construction standards are within strict compliance of ASME Section 1 code requirements.

Steam-Trac 350

The Steam-Trac ST-350 is designed specifically for steam service to 350 PSI. The reflex borosilicate glass has prisms molded into the process side which will display black for water and white for steam.

Glass-Trac: Liquid Level Indicators

Glass-Trac Reflex

Glass-Trac Reflex Gauges use prism glass to provide an excellent indication of the liquid level. All liquids appear black in high contrast to the mirror-like surface above. This clean line of separation can be sighted from many yards away. Reflex Gauges are made in three pressures series (maximum 4000 psig @ 100ºF) and are tapped for ½” or ¾” NPT connections. The standard Glass-Trac level gauges are designed for minimum -20ºF service.

Glass-Trac Transparent

Glass-Trac Transparent Gauges use clear, see- through glass on both sides so that both the color and the interface of liquids can be viewed. Electric lighted gauge illuminators are available for use on Transparent Gauges and provide easy viewing of liquid levels in dimly lighted areas. Transparent Gauges are made in three pressure series (maximum 3000 psig @ 100ºF) and are tapped for ½” or ¾” NPT connections. The standard Glass- Trac level gauges are designed for -20ºF service.

Large Chamber Gauge

Glass-Trac Large Chamber Gauges are made in a special low pressure series of both Reflex and Transparent Gauges. The large diameter chamber makes accurate liquid level readings possible under unusual conditions such as boiling, flashing, or foaming of the liquid. The chamber is manufactured from heavy duty seamless steel pipe with an inside diameter of 2⅛”. Each end of the pipe is closed off with a welded plug which is drilled and tapped for ¾” NPT connections. For close hook-ups, ¾” NPT side connections are made and ends may be drilled, tapped and plugged for cleaning as required.

Welding Pad Gauge

Glass-Trac Welding Pad Gauges are used when standard tank connections cannot be used or when the liquid has solids in suspension. The gauge becomes an integral part of the vessel because it is welded right onto the outer wall. Reflex or Transparent glass is used in any of nine standard lengths. Standard covers are 3⅛” wide.

Armored Tubular: Liquid Level Indicators

Sight Flow Indicator

Questtec Solution’s Sight Flow Indicator is straightforward and dependable way to determine the flow of liquid in a process line for low pressure industrial, sterile, and hygienic applications. Horizontal installation provides direct views through a transparent sight tube for clear visibility. Minimal wetted parts and construction elements make the Questtec Sight Flow Indicator maintenance-free.

Armored Tubular

Questtec Direct-Reading Level Gauges are a simple and reliable way to determine the level of liquid in a tank or vessel, because they give you a direct view without compromising the integrity of your process system. Questtec Armored Tubular level gauges can be used at operating pressures up to 285 psig. For higher operating pressures, use Questtec’s Magne-Trac Magnetic Level Indicator, Steam-Trac, or Glass-Trac Gauges.

Valves

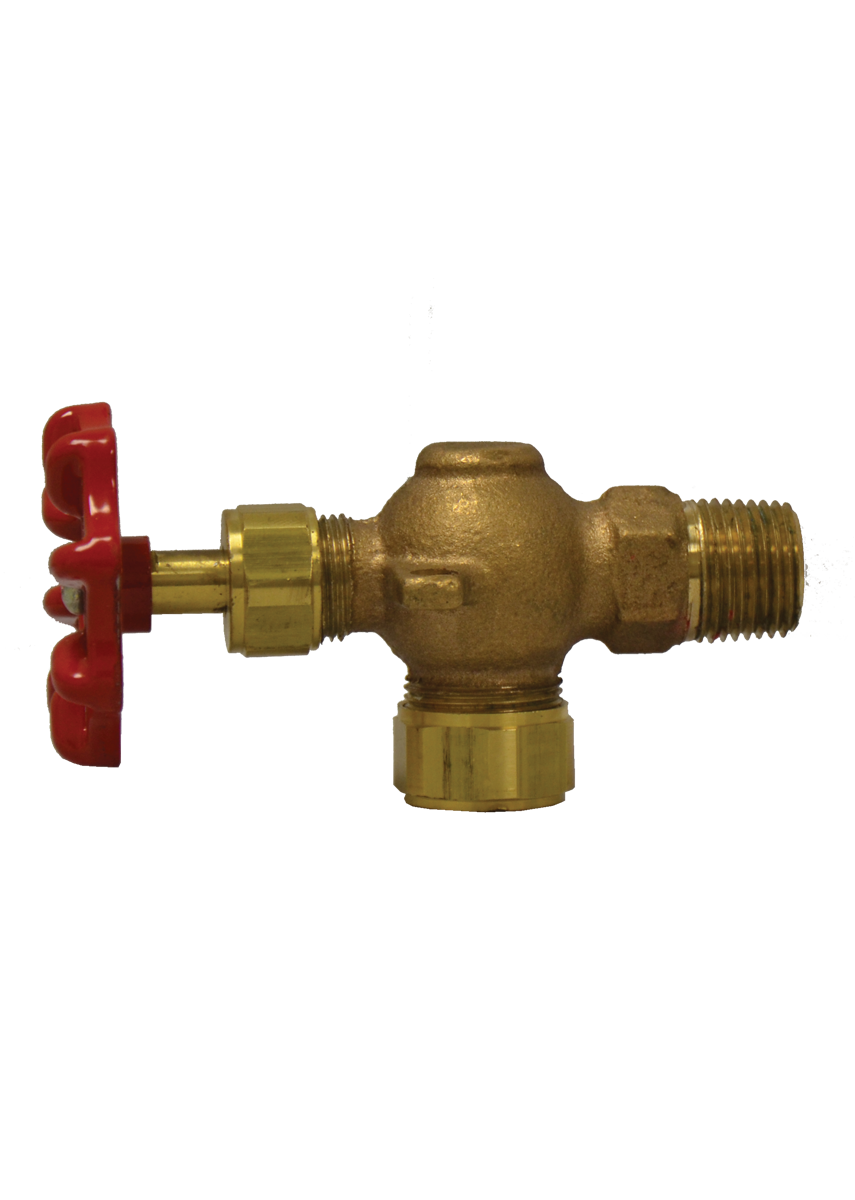

SV - 450

The SV-450 valve is specifically designed for use with a boiler water level gauge glass. This valve is supplied as a valve set including one top valve, and one bottom valve. Each valve has 3 connection ports available in a wide range of sizes and types, (vessel x gauge x vent/drain). The angled flow path facilitates compact installation of the gauge glass, bringing the assembly connection point to the side. The offset body pattern allows a direct path around the stem to clean through the vent/drain ports.

SV-1600

Questtec Solutions Type SV-1600 valves are designed specifically for use with water level gauges in steam/water service. The angled flow path compactly facilitates installation of the level gauge bringing the assembly connection point to the side. The valve has a reciprocating stem that does not rotate, maximizing packing life and preventing galling of the valve seat. The lower valve is normally supplied with a blowdown/drain connection.

Clampseal Valves

Cartridge Replaceable Packing Chamber. Fastest repacking of any valve by swapping bonnet assembly. Minimum packing volume reduces shrinkage and repacking costs. Graphite packing standard on all valves. Other options are available Acme Body – Yoke Connection. Strong and reliable for repeated valve maintenance. Pressure Actuated Backseat: Backseat requires very low torque for total isolation of packing. Provides guide journal for steam, avoiding side load packing.

1S/1U

Glass-Trac Type 1 Offset Gauge Valves are available with screwed (S), union (U), and tubular (T) gauge connections. Type 1 valves are used with Reflex and Transparent Gauges in working pressures up to 4000 psi and with Tubular Gauges to their maximum rating. The Teflon packing ring is standard and used in services up to 450º F. For temperatures to 700º F, valves are fitted with special wire graphite packing. Type 1 valves have stainless steel ball checks to shut off the flow automatically in case of gauge glass breakage.

2S/2U

Glass-Trac Type 2 Offset Gauge Valves are available with screwed (S), union (U), and tubular (T) gauge connections. Type 2 valves are used with Reflex and Transparent Gauges in working pressures up to 4000 psi and with Tubular Gauges to their maximum rating. The Teflon packing ring is standard and used in services up to 450º F. For temperatures to 700º F, valves are fitted with special wire graphite packing. Both valves have stainless steel ball checks to shut off the flow automatically in case of gauge glass breakage.

3S/3U

The Glass-Trac Type 3 Offset Gauge Valve has the Outside Screw & Yoke design which prevents excessively hot and corrosive fluids from contracting stem threads, causing possible malfunction. The stem backs directly off the regrindable valve seat using the positive, non-rotating stem principle. The valve is offset for ease in gauge cleaning and comes in both screwed (S) and a union (U) gauge as standard. On special order, tubular (T) gauge or other type connection can be supplied. Type 3 valves are used with Reflex and Transparent Gauges in working pressures up to 4000 psi.

4S/4U

The Glass-Trac Type 4 Straight-Thru Gauge Valve is available with screwed (S) and Union (U) gauge connections and used with Reflex and Transparent Gauges in working pressures up to 4000 psi. The “straight-thru” valve body design is popularly used with close hook-up (side connection) gauges because the gauge side connection centers and vessel centers can be identical. (With offset valves, vessel centers must be inside or outside side connection centers.) Type 4 Valves have a ¾” NPT Male Tank Connection as standard, with other connections available on order.

5S/5U

Glass-Trac Type 1 Offset Gauge Valves are available with screwed (S), union (U), and tubular (T) gauge connections. Type 1 valves are used with Reflex and Transparent Gauges in working pressures up to 4000 psi and with Tubular Gauges to their maximum rating. The Teflon packing ring is standard and used in services up to 450º F. For temperatures to 700º F, valves are fitted with special wire graphite packing. Type 1 valves have stainless steel ball checks to shut off the flow automatically in case of gauge glass breakage.

7S/7U

The Glass-Trac Type 7 Offset Gauge Valve features the Outside Screw & Yoke (OS&Y) design which prevents excessively hot and corrosive fluids from contacting stem threads. The stem uses the positive non-rotating stem principle and backs directly off the regrindable seat. This valve is offset for ease in gauge cleaning and is available in screwed (S) and union (U) gauge connections. The Type 7 Valve also has a backseating stem as a standard feature. Stainless steel ball checks are available upon request.

1T/2T

Glass-Trac Offset Tubular Gauge Valves are identical to Type 1 and 2 S and U Valves except they are fitted with the ⅝” O.D. tubular glass connection. The Type 2T Valve also can be furnished in the coarse thread design and with quick-operating lever for remote operation by chain. Both valves have a molded Teflon packing ring and rubber glass gaskets as standard for services up to 250º F. For temperatures to 425º F, valves have wire-graphite packing and Viton® glass gaskets. In the event of tubular glass breakage, a stainless steel ball check closes the valve to prevent further loss of fluid.

1TC

For low pressure water vessels, storage tanks, containers, etc. Glass-Trac provides Type 1TC carbon steel and 316 stainless steel valves for Tubular Gauges. These valves are used with 5/8”, ½” or ¾” O.D. Pyrex Red Line, High Pressure or Heavy Wall Glass. Each valve contains a Stainless Steel ball check which closes the valve in the event of glass breakage.

5S/5U

For low pressure water vessels, storage tanks, containers, etc., Glass-Trac provides Type OT Brass Valves for Tubular Gauges. The valves are made up with 5/8” O.D. Pyrex Red Line, High Pressure or Heavy Wall Glass from stock. Each valve contains a brass ball check which closes the valve in the event of glass breakage. Two guard rods are used. The lower valve also is fitted with a threaded drain cock. Type OT Brass Valves are suitable for working pressures up to 200 psig at or under 400ºF

Illuminators

See-Level LED Illuminator

The Questtec Solutions See-Level LED Illuminator for hazardous locations utilizes the latest technology to provide brilliant green back lighting to any process gauge. Innovative circuitry allows for the use of an individual light source every ½” along the length of any gauge. With a life span of over 100,000 hours each, the LED’s last 200 times longer than incandescent bulbs. Even in the event of an individual lamp failure, the design provides lighting overlap ensuring that the fluid level is always illuminated.

Stream-Trac STBI-3000A

The Steam-Trac STBI-3000A Illuminator matches long lasting LED lamps to a rugged fabricated enclosure to set an unsurpassed standard of reliability for bi-color water gauge illumination. Each port has 4 each red and green LEDs to provide a brilliant display. To comply with ASME Section I, PG60, a ported gauge must provide a means for obvious discrimination between steam and water. This requirement mandates that a ported gauge must have a working illuminator.

See-Level Amber Illuminator

The Questtec Solutions See-Level Amber Illuminator for hazardous locations utilizes the latest technology to provide brilliant green back lighting to any steam gauge. Innovative circuitry allows for the use of an individual light source every ½” along the length of any gauge.

Guided Wave Radar

Guided Wave Radar

The QTS Guided Wave Radar delivers an independent reading of liquid and solid levels. These top mount, direct insertion radars measure interface and direct level of liquids and solids, both of high and low pressures and temperatures. GWR technology provides dependable level indication through pulsating high-frequency microwave energy down the probe within a bypass chamber. A GWR will read the true level of the process, even if the density diverges over time.